How the Flux?

Using flux is extremely important when soldering connections for several reasons. Most importantly the flux will clean your solder joints and help to eliminate oxidation. Flux will also help to “wet out” your solder joint leading to quicker heat transfer much better solder flow, ultimately leading to better electrical contact.

It is recommended to use flux each time you solder or desolder a joint for those reasons, however your choice of flux is just as important as using it.

A while ago we were called in to investigate why one of our clients was having an issue with intermittent colour flashes while using our RGBA single chip ribbon with one of our ProSpeed 4-LITE controllers. We joined the customer on-site within a few hours and spent some time trying to figure out what was causing the issue.

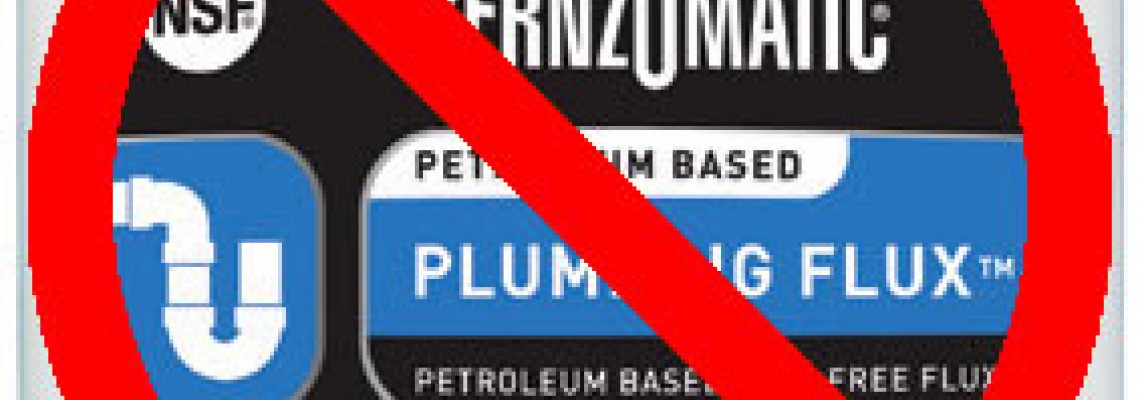

The client had no issues with the soldered joints during their initial tests, but once the array sat for a while and was turned back on the intermittent colour flickering started to happen. A quick look and the soldered joints all appeared to be good, and the client was using a good amount of flux when soldering, but they were still having issues. A quick look around the workbench turned up a pot of Bernzomatic Flux.

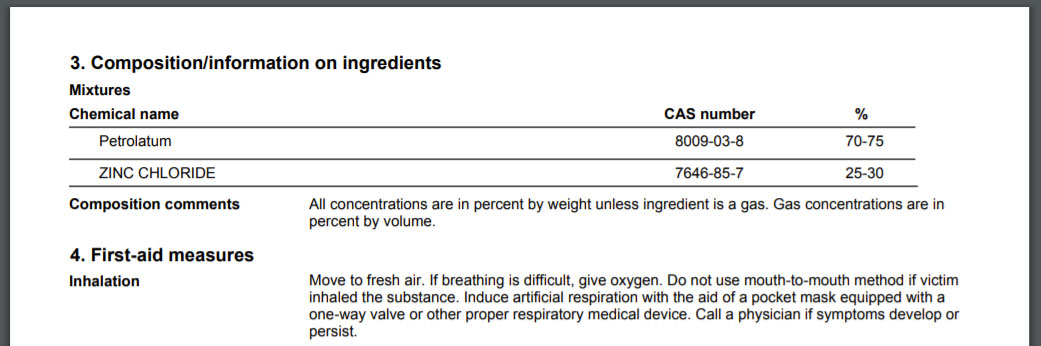

Image: Properties of Bernzomatic Flux

Bernzomatic Flux is a plumbing flux that contains Zinc Chloride. Zinc Chloride is highly conductive when wet, but when dry it becomes non-conductive. So, what was happening was that the Zinc Chloride crystals were being dried out by the heat from the soldering process, and the ribbon initially was testing well, but the Zinc Chloride crystals are still left behind. Being hygroscopic the Zinc Chloride would pull moisture from the air into itself creating small intermittent shorts between the soldered joints on the ribbon. The heat from the ribbon would in turn release the moisture from the Zinc Chloride crystals making the Zinc Chloride no longer conductive and the process just endlessly repeats itself.

I had seen these same symptoms a few months before while shooting Umbrella Academy Season 1. They were running a similar array of LED ribbon on some RC4 Wireless dimmers. During that investigation, the soldered joints looked dirty and there was a lot of spittle and spatter around the joints. A good scrubbing of the soldered joints temporarily fixed that issue on set, but unfortunately a full investigation into the issue was not possible before we moved on to another location.

No amount of cleaning will ever remove the Zinc Chloride crystals that are left behind from this type of flux, and this is one of the reasons it is so important to chose a high quality electronic flux for any electronic soldering project. You can purchase high quality electronics paste flux from any local electronics supplier.