COVID-19 RESPONSE

We are sure that everybody out there is tired of hearing about what companies are doing in response to COVID-19, frankly so are we because most of the information is pretty irrelevant. So to keep it short, we are very lucky to be a company with a relatively low overhead and we are working in an industry that is already shut down, so our response was easy to come up with.

Continue to work from home expanding our product line and continue to develop the depth of our website making things easier for our customers when our clients need us. For instance the downtime has given us time to add this news section to our website, so we can let everyone know what we are doing and what products are coming down the pipeline.

We are already fully restocked and ready for when things ramp back up and we are standing by for when things return to normal.

We are also doing our best to help our front line workers fight COVID-19 in our own little way.

Some of you know that all of our recent prototyping has been done using 3D printing to build out sample products and we have also been using them to create custom products for our customers. For those that don't already know about this service, we have been 3D printing for over three years.

It turns out that this has been good practice for us as we now shift our 3D printers over to the COVID-19 response. We are working with Ink Smith on an initiative to make as many protective face shields as possible in order to counter the current shortage. Ink Smith put out a call to all owners of 3D printers to help produce as many face shields as possible for the front-line medical community, we immediately offered ours up to the campaign.

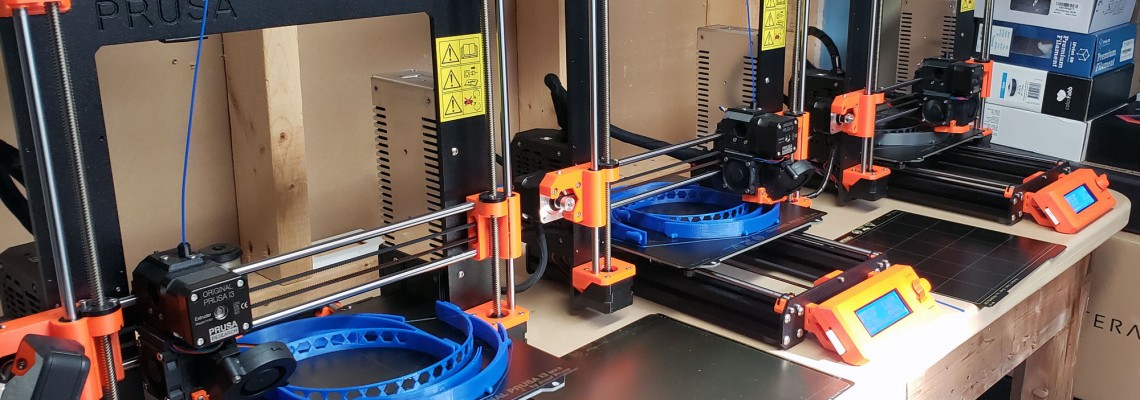

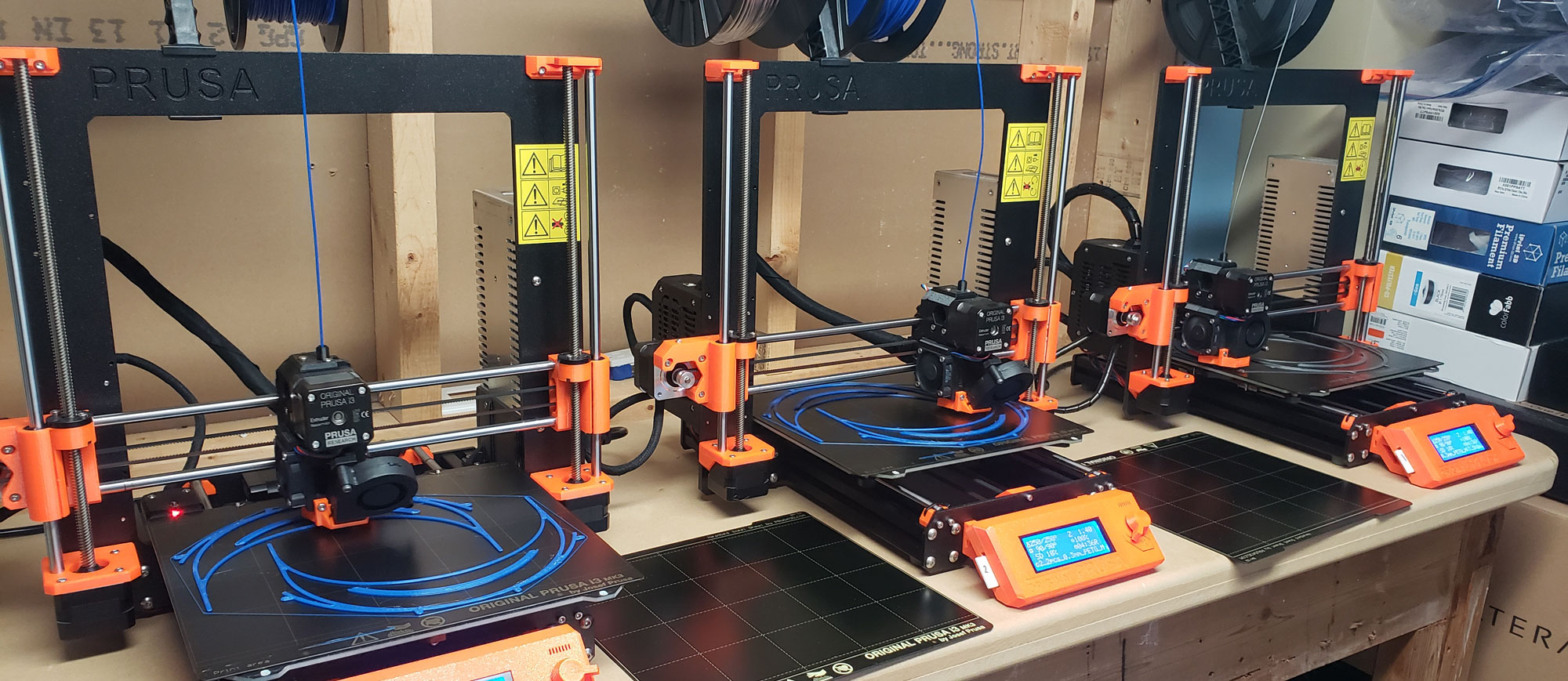

Image: Starting our first run of 6 face shield frames.

Image: Starting our first run of 6 face shield frames.

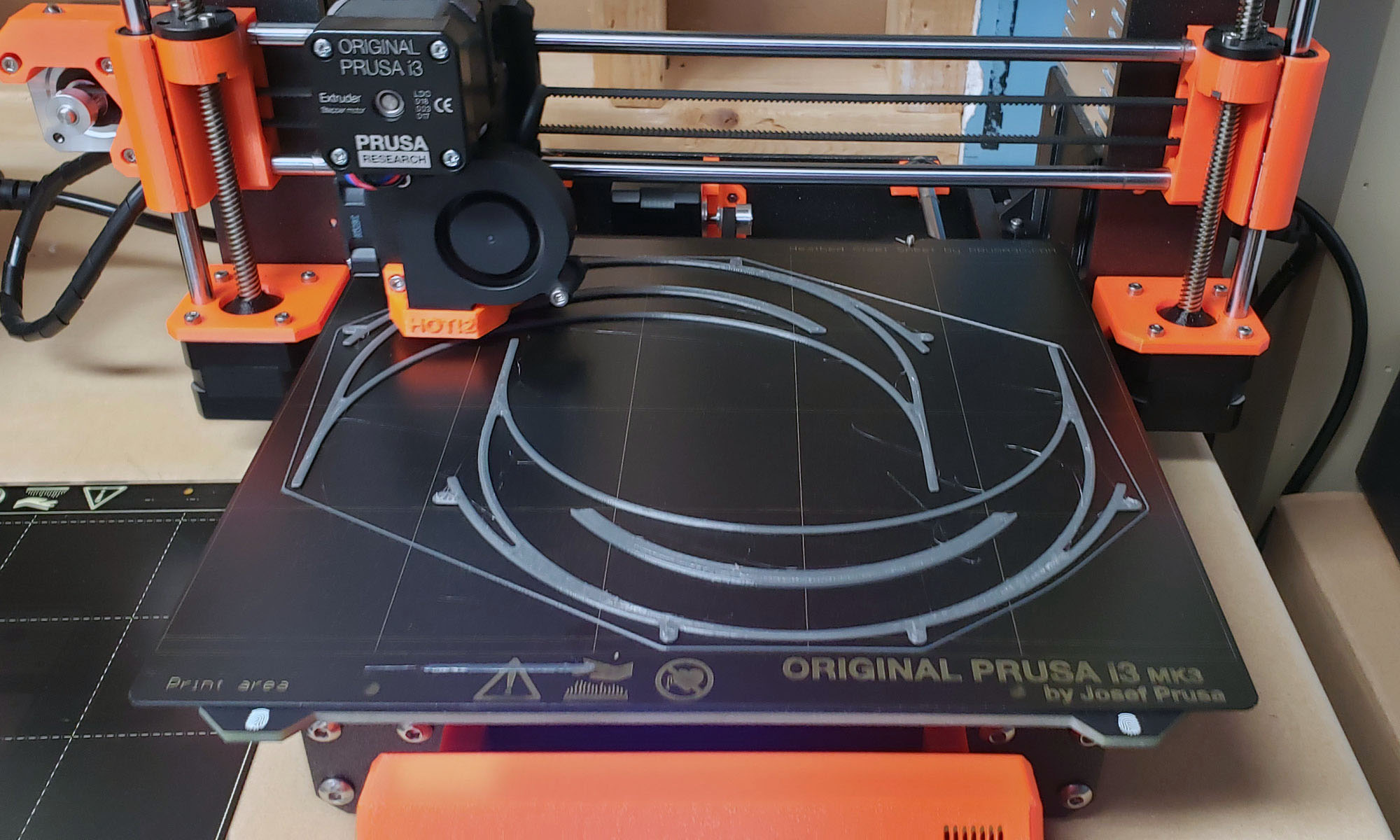

By utilizing the Prusa 3D printed face shield design Ink Smith is working with Health Canada to get these distributed to our front line staff that need them. Ink Smith will also be taking care of laser cutting the clear lenses, sanitizing all of the printed parts and distributing the face shields.

We are currently producing over 20 assemblies per day and by the end of the week we hope to have helped create over 100 masks to help our front-line workers.

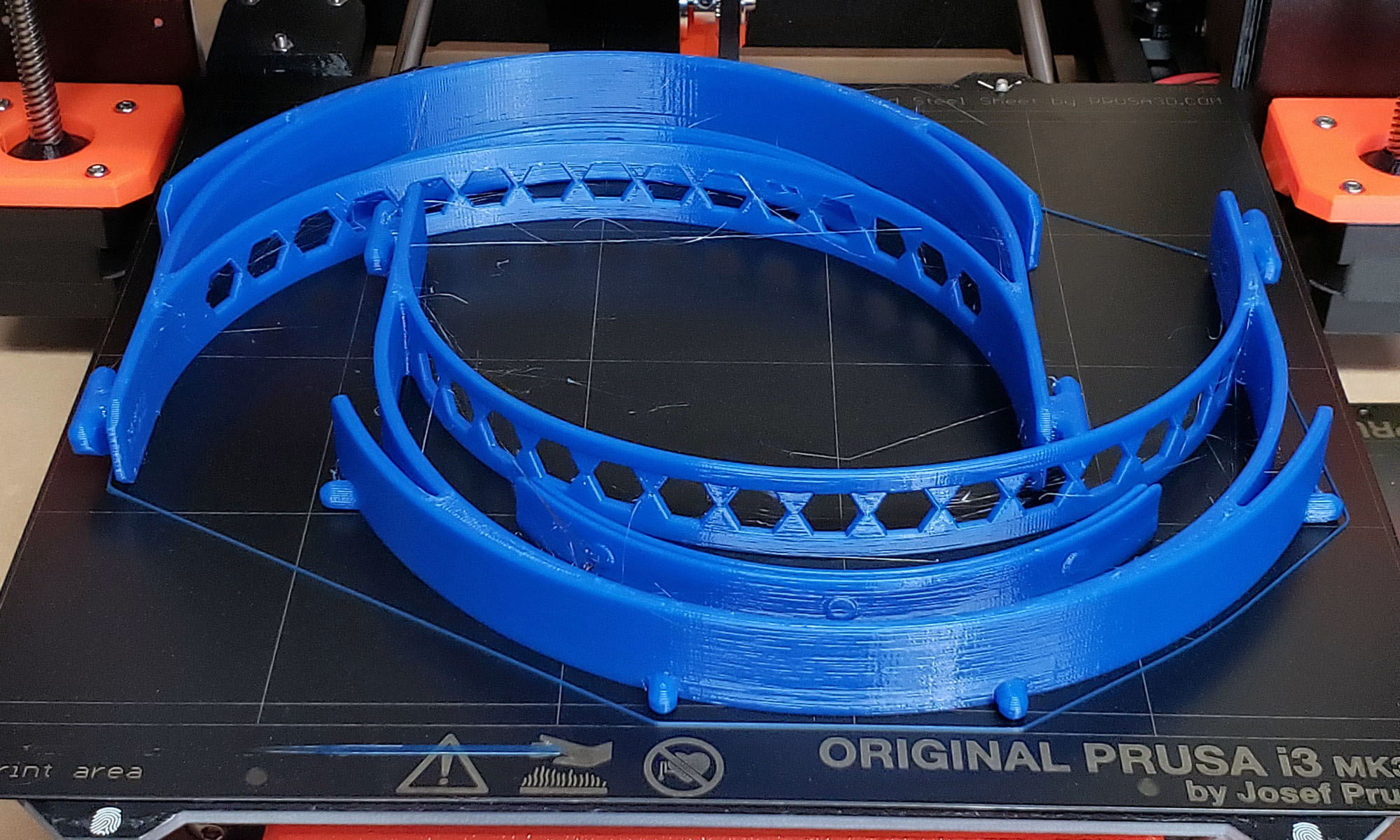

Image: The first run is almost complete. After a quick cleanup these will be ready to ship!

We encourage you to practice physical distancing and keep yourselves safe while flattening the curve for others and we look forward to seeing you when things return to normal!